The new Non-Contact CAN Sensors SP7001/7002 are scheduled for release in December 2019.

Building upon the concept of the SP3000 Non-Contact Voltage Sensor , the new SP7001/7002 are specifically engineered to safely detect CAN-bus signals.

1. Detect in-vehicle CAN FD (CAN flexible data-rate) and CAN frame signals from above the wiring insulation

The new Non-Contact CAN Sensors let you detect the electrical signals in a CAN frame without any metallic contact simply by hooking the sensor onto a CAN bus cable. The SP7001 supports the CAN FD protocol, and the SP7002 is compatible only with networks following the CAN protocol. In the development and verification of CAN systems, engineers typically need to peel off part of the wiring insulation to directly probe or clip the metal wiring, or attach a sub-harness to the cables in order to capture the signal actually flowing through the cables. The issues with these methods are clear:

- Extra time is needed to enable direct probing or attach a sub-harness

- Compromised cables need to be replaced

- The electrical characteristics of the CAN bus can be affected with direct probing, which may in turn affect the operation of the ECU. Some ECUs may shut down by design due to unexpected signals.

Because the SP7001/SP7002 can detect signals from outside the cable insulation, users can significantly reduce R&D and validation times and avoid the above other issues as well.

2. Ideal for public road testing

Vehicles need to be field tested on actual roads before going to market. Real road conditions make it difficult to stabilize alligator clips onto the CAN cables, making the SP7001/SP7002 ideal for this type of testing. By simply hooking the sensor onto the cable, no additional modifications to the car is required. The SP7001’s support for CAN FD lets researchers efficiently test and develop next generation vehicles with larger payloads per transmission.

3. Compatibility with a diverse range of CAN interfaces

The CAN sensors can be connected to the industry-standard D-sub 9pin interface, letting customers use the products with their existing CAN FD/CAN analysis systems from the get-go.

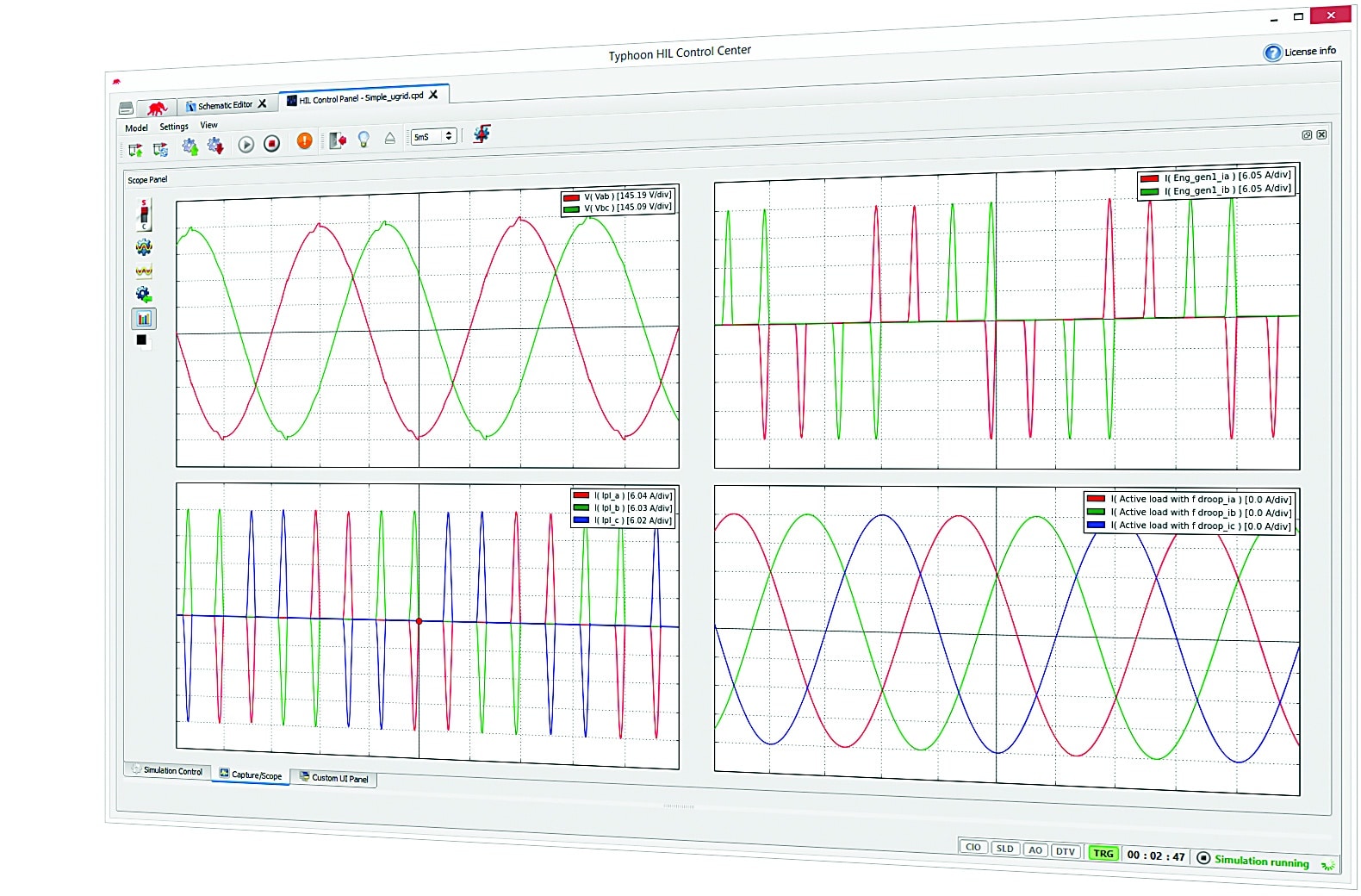

sampling time and ultra-low latency, offering 16 Analogue and 32 Digital inputs and outputs this HIL instrument sets the industry standard for real-time emulation of power electronics systems.

sampling time and ultra-low latency, offering 16 Analogue and 32 Digital inputs and outputs this HIL instrument sets the industry standard for real-time emulation of power electronics systems.