28th - 29th February 2024

National Motorcycle Museum, Solihull - B92 0EJ

The MDL team, as part of APC Technology Group, will be exhibiting at the Future Propulsion Conference as a silver sponsor. The annual two day UK event will bring together industry and academic experts within the powertrain development field.

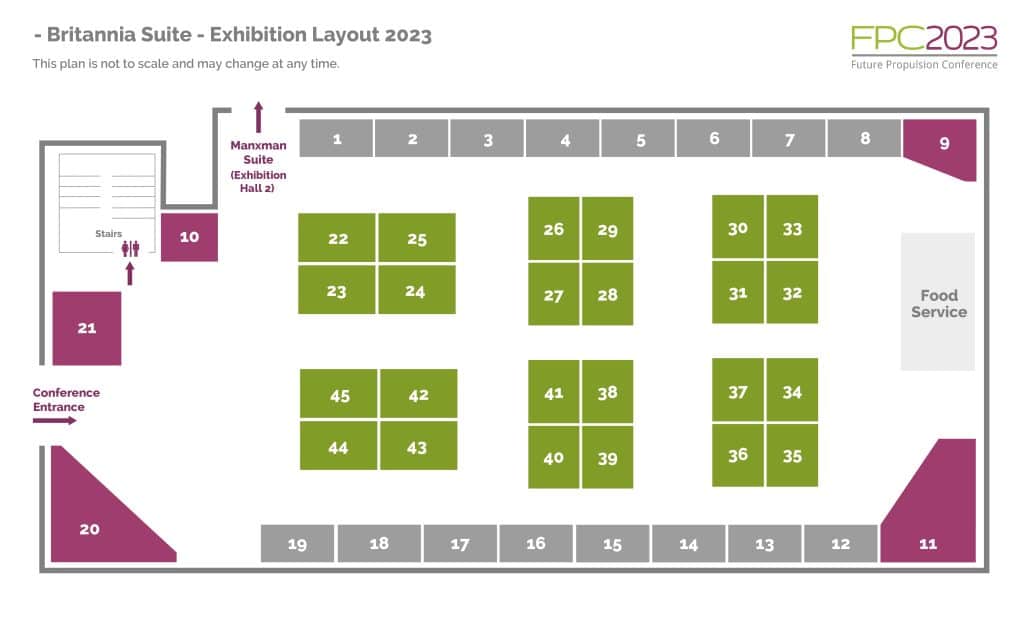

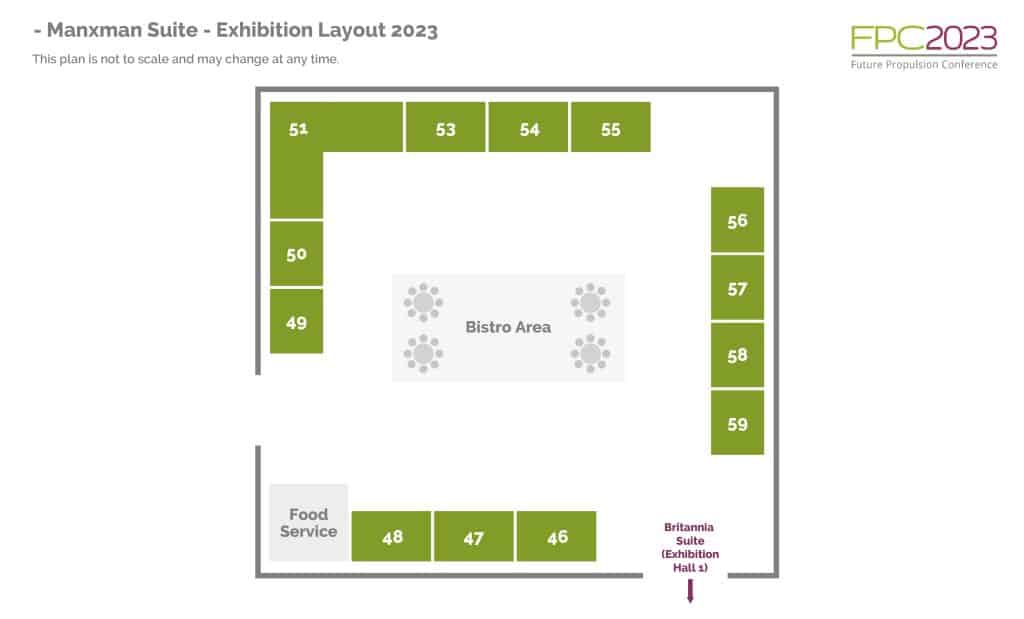

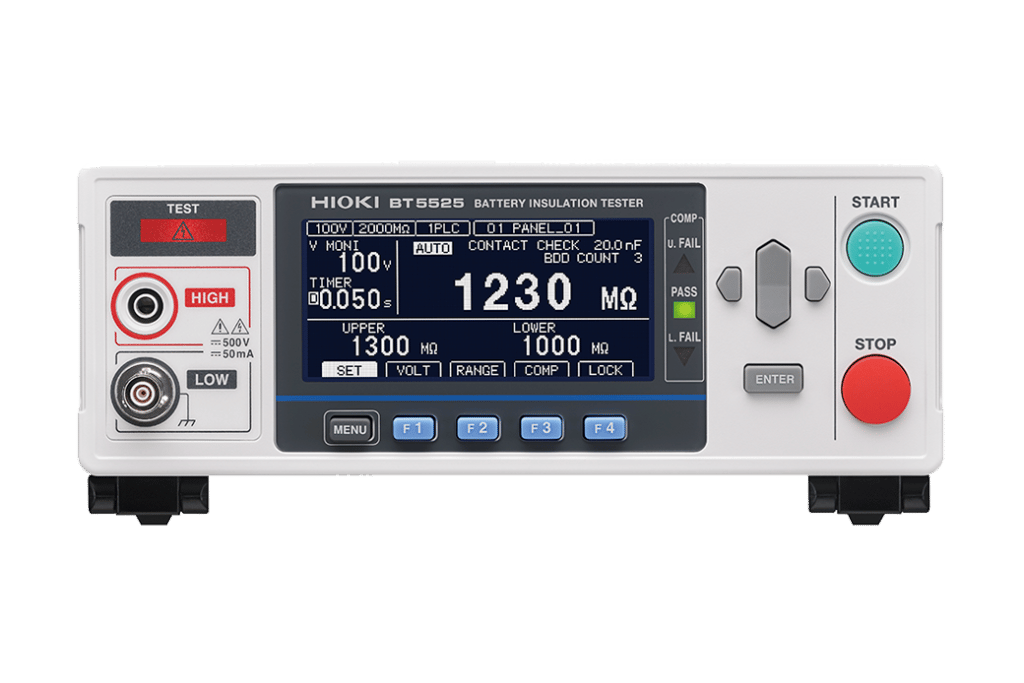

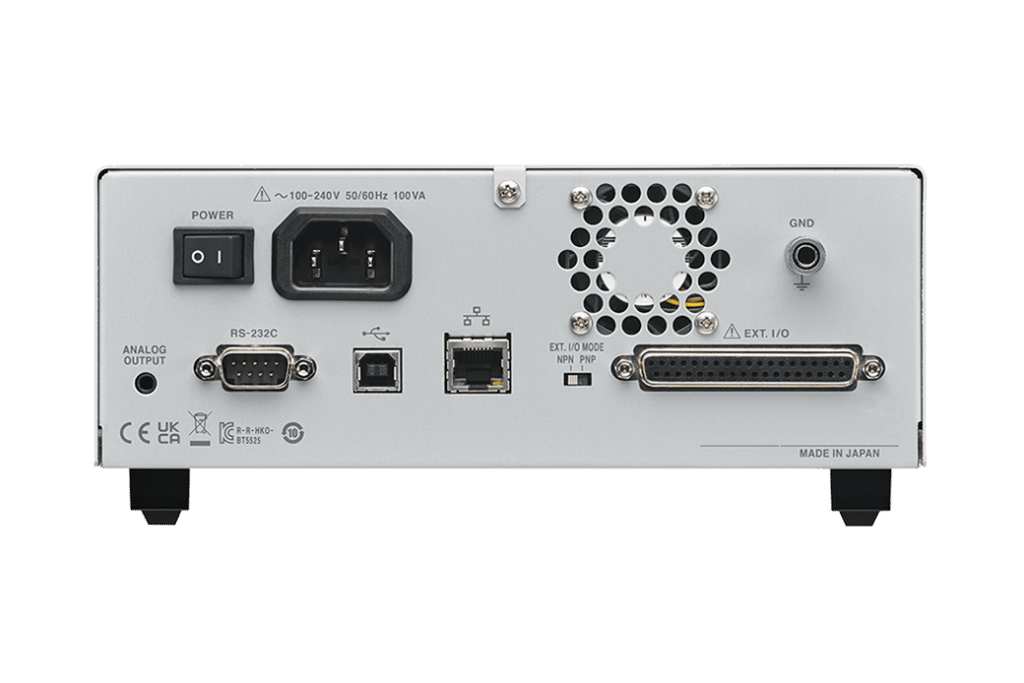

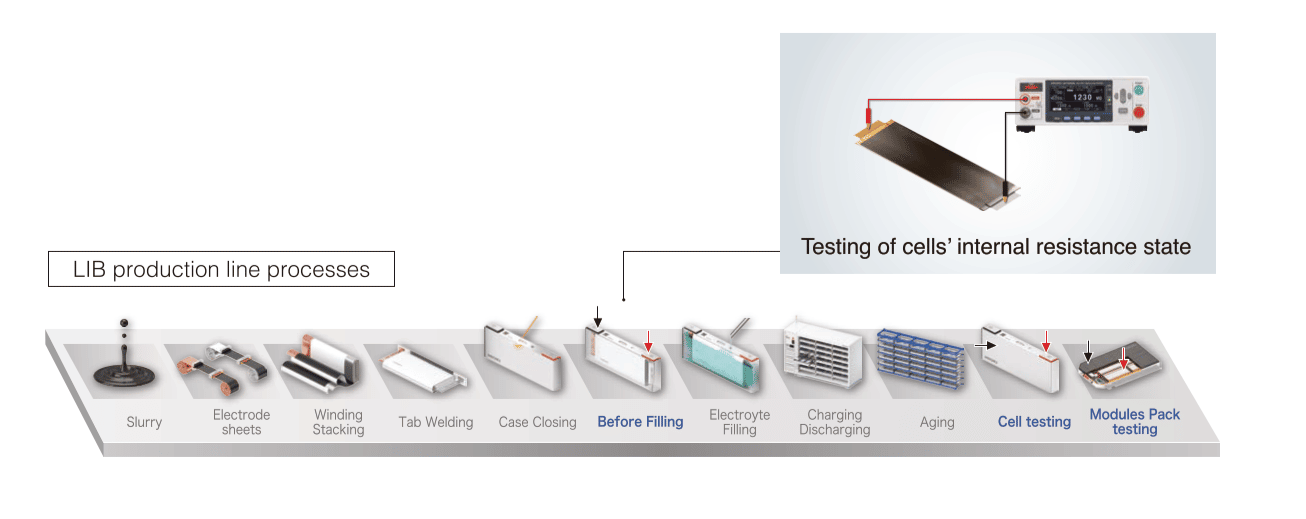

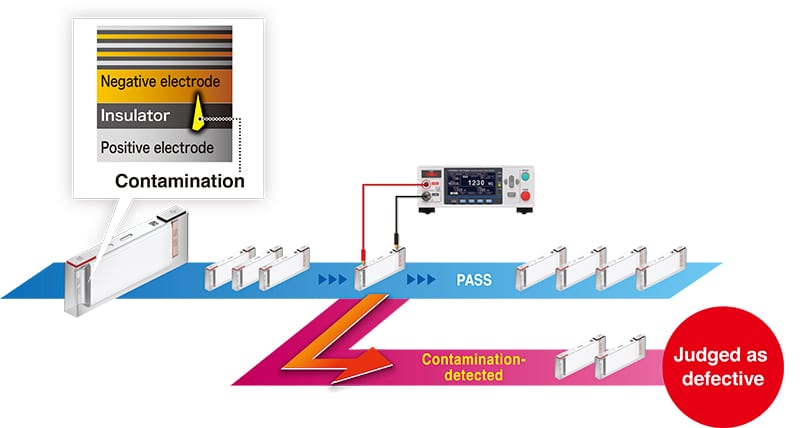

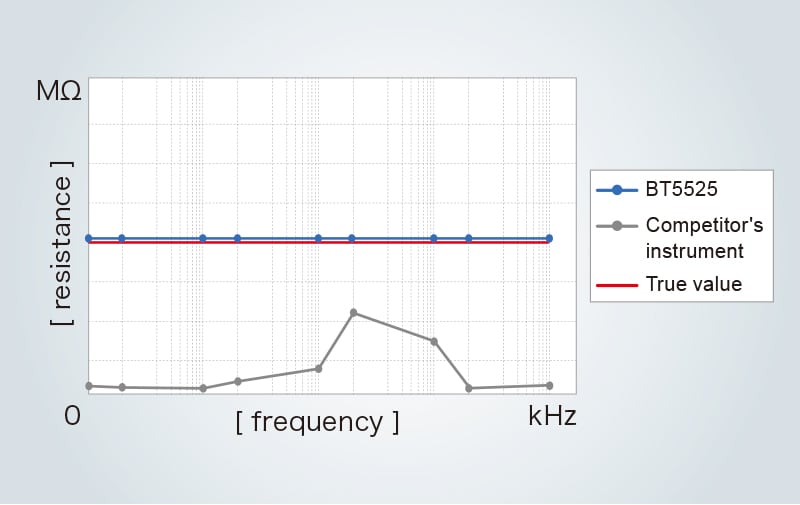

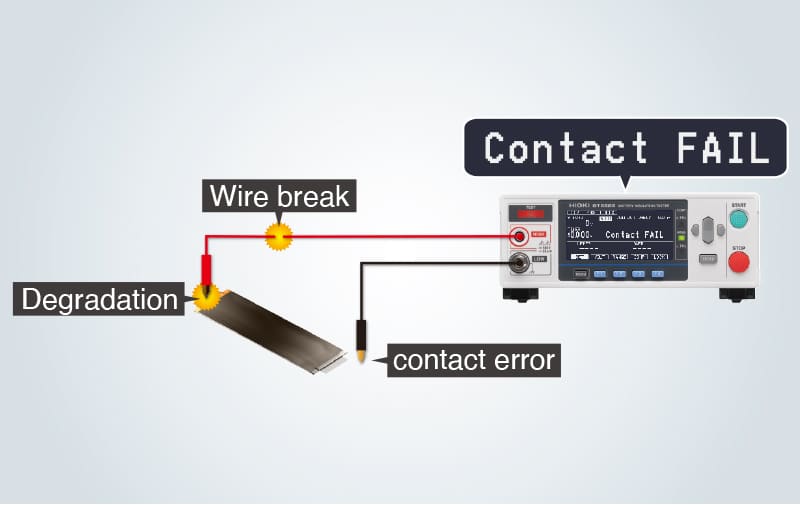

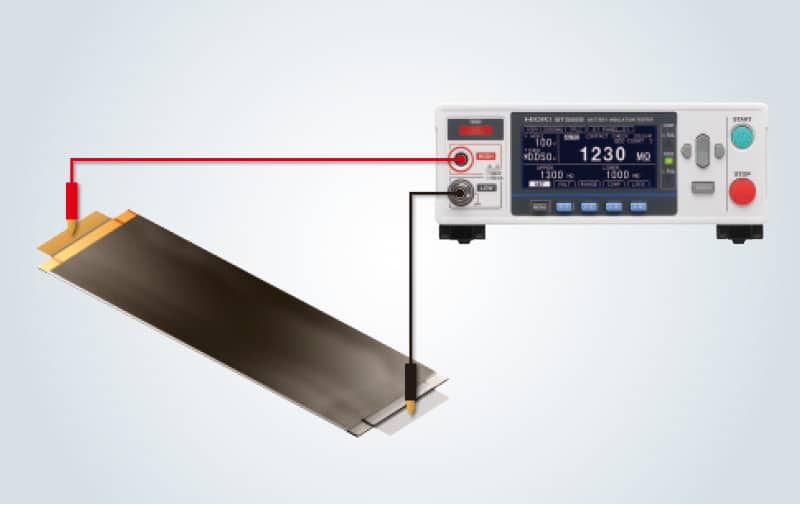

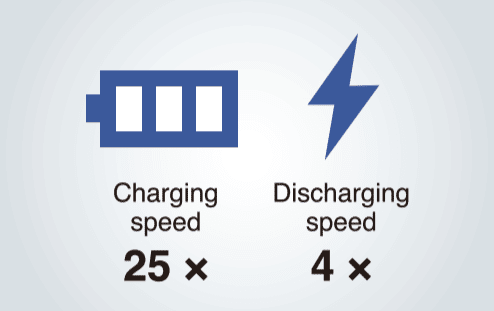

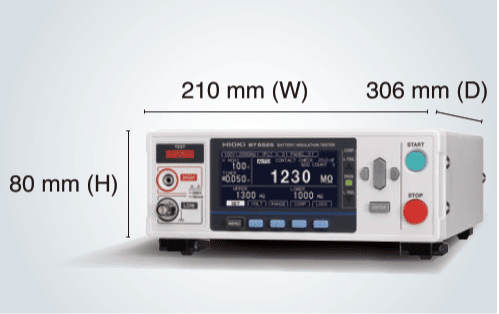

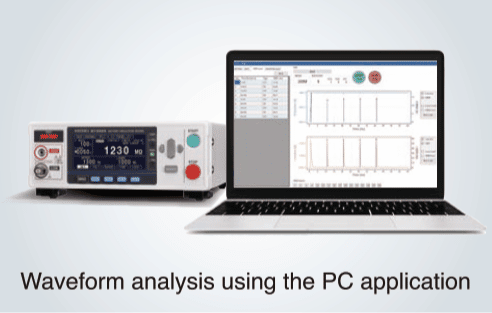

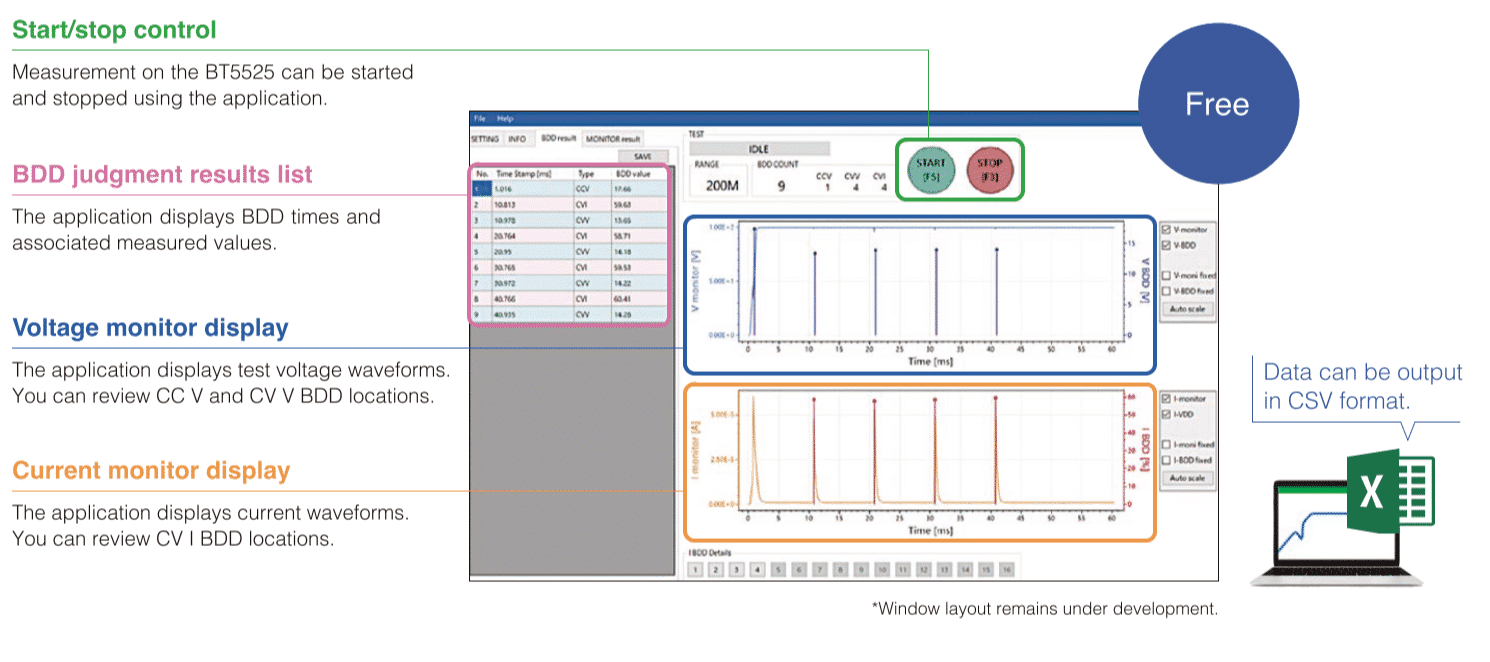

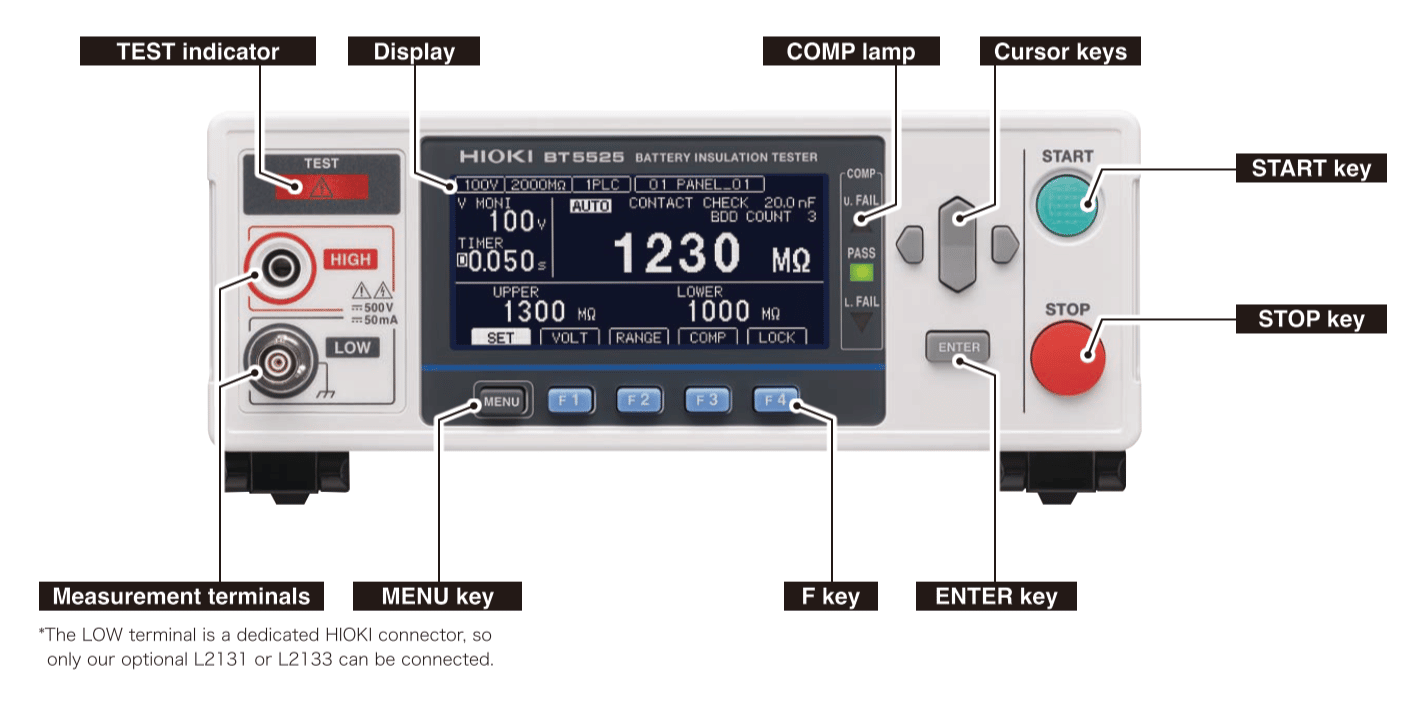

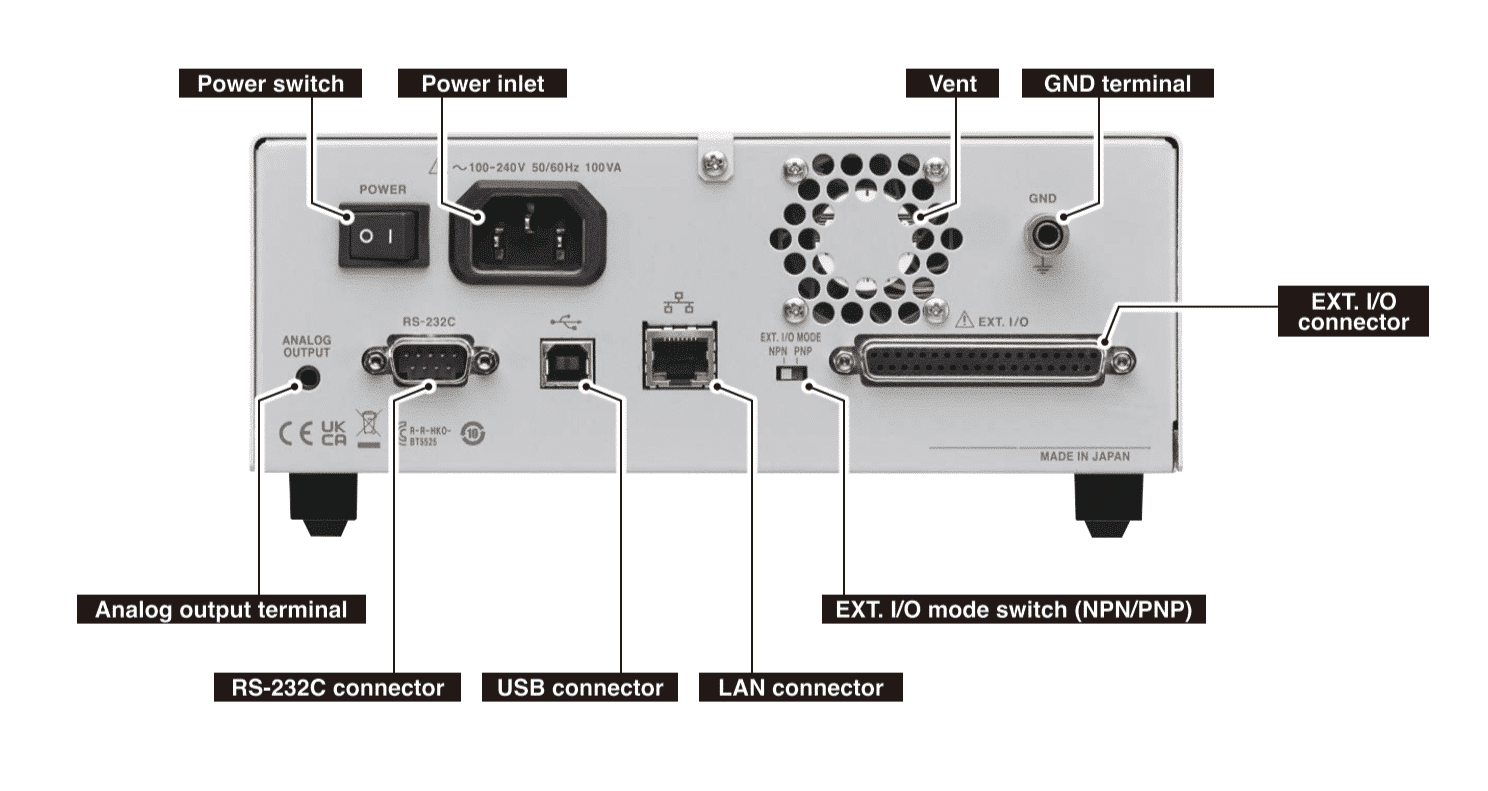

We will be showcasing a range of test solutions at Booth 34 in the Britannia Suite, from manufacturers including Kewell, Hioki, Chroma, Keysight and Tektronix.

The Future Propulsion Conference (FPC2024) is a two day UK event created to bring together industry and academic experts within the propulsion development field. It will open up presentations and discussions on the solutions to the challenges faced by the engineering industry in the UK and internationally over the next ten years.

MDL Technologies will be on hand to answer any queries you have about electric vehicle, low carbon and other testing requirements you may have.

For more information about Future Propulsion Conference 2024, or to register for a visitor ticket, head to their website using the button below.

The test and measurement experts who will be at FPC 2024 from MDL Technologies, get in contact to arrange a meeting: