The BT3561A, BT3562A and BT3563A Battery HiTesters from Hioki. These three upgraded models offer highly reliable performance to measure the quality of batteries from cells to large packs up to 300V, and a newly equipped LAN interface.

Designing automatic battery testing systems is easier and faster than ever before

– Double the total line resistance, so measurement errors are less likely to occur when using long measurement cables

– Stable operation regardless of increased total line resistance due to probe and relay degradation

– LAN is equipped as a standard for easy system design and layout, and excellent noise resistance for stable operation

– Improved electrostatic resistance as a countermeasure against electrostatic charges during battery transport on a production line

Reducing test system development cost and management man-hours

The new BT356xA has dramatically improved tolerances for line resistance compared to previous models. This improvement makes it easy to build test systems with large numbers of channels using relays. Additionally, a longer maintenance cycle for systems in use means fewer maintenance man-hours. Finally, its capability to handle thinner cables than with previous models* makes it easier to route cables.

*AWG 29 (0.064 mm2) wire equivalent to 2.2 Ω over a 8 m round trip can be used with the 3 mΩ or 30 mΩ range.

Preventing instrument malfunctions caused by static electricity

Batteries can become charged on production lines, for example, when being transported on a conveyor belt. When probes are placed in contact with such batteries, the resulting application of static electricity can then damage the instrument. The BT356xA series is designed to withstand contact with ±30 kV of static electricity*, preventing static-caused malfunctions and reducing testing line downtime.

* ±30 kV IEC 61000-4-2 contact discharge

These highly advanced battery testers are best suited for shipping and acceptance inspections of cells and battery packs. They simultaneously measure internal resistance and the battery’s open-circuit voltage (OCV).

Since the AC-IR measurement method is used, the measurement time is shortened. In addition, highly repeatable results are attained with this method. These testers have a highly accurate 3 mΩ range, allowing for a resistance measurement of battery tab welding and bus bars. All of this combines for the best choice in battery testers.

Measuring battery performance and safety using internal resistance (AC-IR) and open-circuit voltage (OCV)

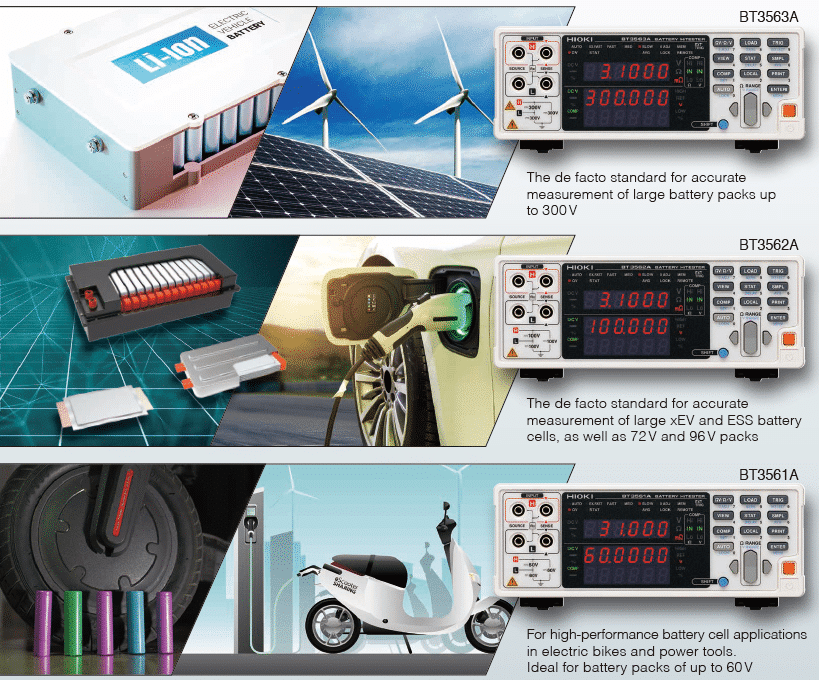

BT3561A

– Small cells for power motors, Small packs of up to 60 V

– Voltage measurement ranges: 6 V/60 V

– Resistance measurement ranges: 30 mΩ/300 mΩ/3 Ω/30 Ω/300 Ω/3 kΩ

BT3562A

– Large cells for xEVs, Mid-sized packs of up to 100 V

– Voltage measurement ranges: 6 V/60 V/100 V

– Resistance measurement ranges: 3 mΩ/30 mΩ/300 mΩ/3 Ω/30 Ω/300 Ω/3 kΩ

BT3563A

– Large packs for xEVs, Large packs of up to 300 V

– Voltage measurement ranges: 6 V/60 V/300 V

– Resistance measurement ranges: 3 mΩ/30 mΩ/300 mΩ/3 Ω/30 Ω/300 Ω/3 kΩ

Want further information, advice or a quote? Speak with our expert consultants about any of the Hioki products available on 01462 431981, or contact us here.