In the development of automotive electrical control systems, it is important to measure and validate a diverse array of current levels among components such as:

- Drive current of various motors in the order of several amperes

- Inrush current, for example at motor start, in the order of several tens of amperes

- Minute control signals of about 1 mA

- Standby current

The need to measure such a wide range, from micro standby currents to inrush currents that can reach tens of amperes traditionally necessitate the use of separate sensors equipped with the appropriate range so that resolution and accuracy are not sacrificed. Using a higher range current sensor to measure low standby current will reveal no meaningful result, while sensors with a low range will not be able to handle high currents safely.

Hioki provides a solution for this particular application with the CT6710 (50MHz bandwidth) and CT6711 (120MHz bandwidth) current probes (based on the zero-flux current sensing method using Hall Element detection), both of which offer three separate ranges to meet an expansive range of measurements in a single unit. More on this below:

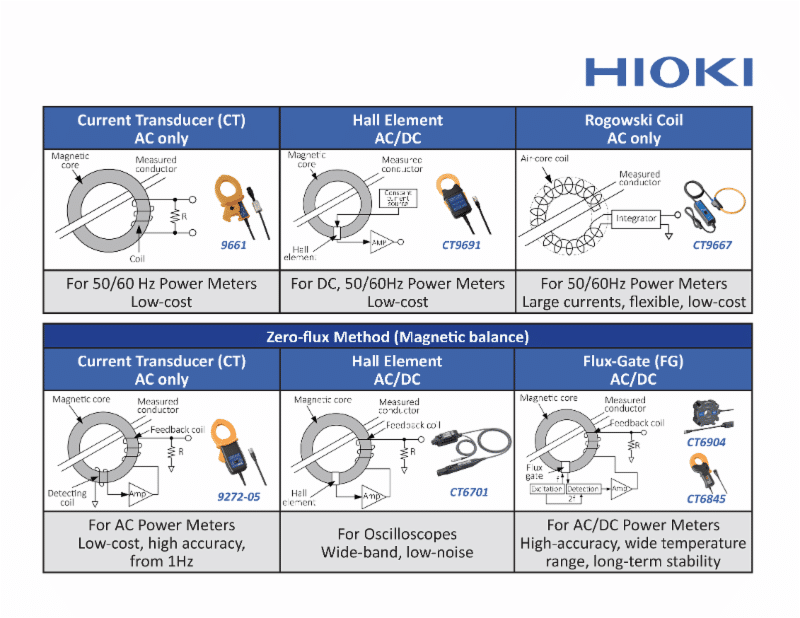

Zero Flux AC/DC Current Sensing using Hall Element

In the zero-flux method, in order to cancel out the magnetic flux produced inside the magnetic core by the AC current flowing in the conductor being measured, a secondary current flows to the secondary side of the feedback winding. The magnetic flux existing in the low-frequency regions that cannot be cancelled is detected using a CT, Hall element, or Flux gate element, upon which a secondary feedback current is generated through an amplifier circuit so as to cancel out the magnetic flux in the low Hz regions. This secondary current flows to the shunt resistor, producing a voltage that is proportional to the current flowing in the conductor being measured.

The Hall element detection method is represented by the Hioki Models 3273-50 , 3274 , 3275 , 3276 , CT6700 , CT6701 , CT6710 , and CT6711 , all of which deliver the following key characteristics:

- Similar to the CT detection method, sensor operation depends on canceling out the magnetic flux in the magnetic core, giving it excellent linearity unaffected by the magnetic core’s B-H magnetic characteristics.

- Since the probes operate using the CT of the secondary feedback winding in the high-frequency region, and utilize an amplifier for the low-frequency region, a broad frequency bandwidth is supported.

- Like the flux-gate element detection method that will be discussed in the next installment, due to lack of excitation current noise, overall noise is extremely low.

Note that:

- The Hall element used in Hioki current probes is developed and manufactured in-house using a compound semiconductor called indium antimonide (InSb), which while delivering high-sensitivity, is susceptible to temperature drift due to its sensitivity to the surrounding temperature.

Because the zero-flux method achieves extremely stable measurements by driving the negative feedback characteristics of the magnetic circuit, thus reducing the effects of the magnetic core, it is capable of delivering a wide frequency band and improved linearity, factors that contribute to the optimization of the current sensor’s performance. Such characteristics are ideal for these AC/DC applications:

- Current testing of ECU and instrumentation systems in automobiles, e.g., dark current, large current, operating current of various motors

- Current consumption testing of wearable devices, e.g., battery-operated devices and their sensors

- Performance evaluation of high speed switching devices, e.g., monitoring the current waveform of SiC, GaN or other types of advanced components