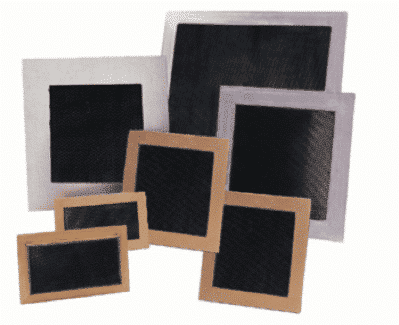

EMI/RFI Shielded Waveguide Air Vents

Shielding effectiveness and air flow performance are improved with durable waveguide air vents produced by ETS-Lindgren’s exclusive solder fusion process. This proprietary manufacturing process ensures absolute performance by completely fusing all contact surfaces in the honeycomb matrix to create a continuous, solid electrical and mechanical bond that will not separate or permit RF leakage.

The electric field, plane-wave, and microwave shielding effectiveness of the brass or steel honeycomb is virtually identical because of the consistency of the solder fusion process. Steel provides higher low-end magnetic field shielding effectiveness. However, brass can satisfy non-ferrous requirements and is favoured in areas of high humidity.